What should be paid attention to when soldering pogo pins?

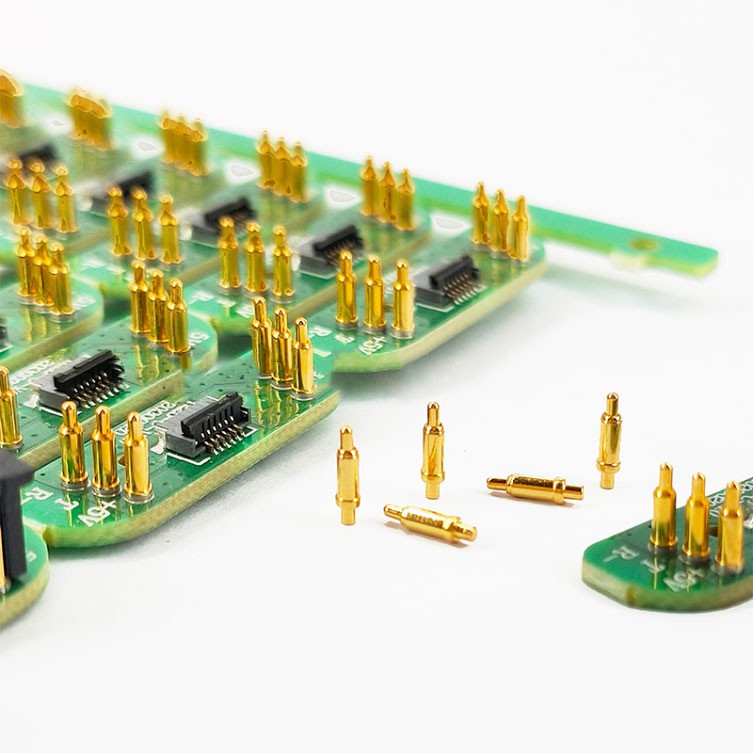

Like most connectors, pogo pins have a certain degree of heat resistance. Standard core and spring materials cannot withstand heat or a one-time tin reflow process. If you plan to repeat the operation, please contact us and we will assist you to choose the probe and material that best meets your needs, so as to avoid follow-up problems.

How do you design a circuit board (PCB) size for a pogo pin connector?

Generally speaking, the radius distance of the circuit board should be reserved more than 0.3mm at the end of the pogo pin, the radius of the solder paste surface should be reserved more than 0.4mm for the convex ring, and the length of the tail end should be at least 0.4mm more than the thickness of the circuit board. But of course, the above data should be based on reasonable inner tolerance and minimum single needle spacing.

How to design flexible circuit board (FPC) dimensions for pogo pin connectors?

It is not much different from the general circuit board. The biggest difference is that after deducting the flexible circuit board, an extra 0.1mm should be reserved at the tail of the single needle.

How to size a circuit board (PBC) for soldering pogo pin connectors?

For the part in contact with the solder paste, an extra pogo pin radius of 0.5mm should be reserved.